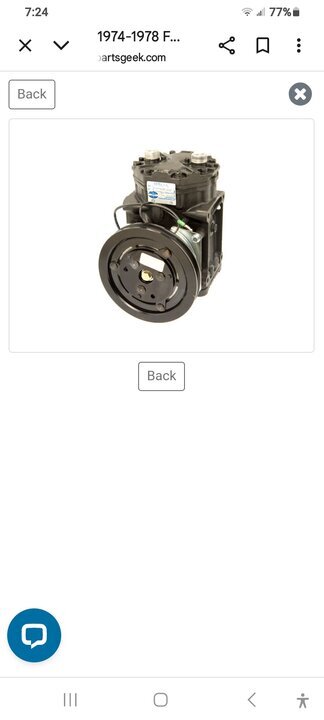

Getting ready to do my first clutch tomorrow. I'v researched everything I can find online. Engine off to burnish? Get it off with a bolt not a puller? Will I need to use a gauge or tape to set a clearance? Any helpful tips so I don't screw it up would be helpful. Got the clutch from Napa. Oh and someone said to turn on the pump clutch when burnishing the new clutch?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cds clutch

- Thread starter scotty747

- Start date

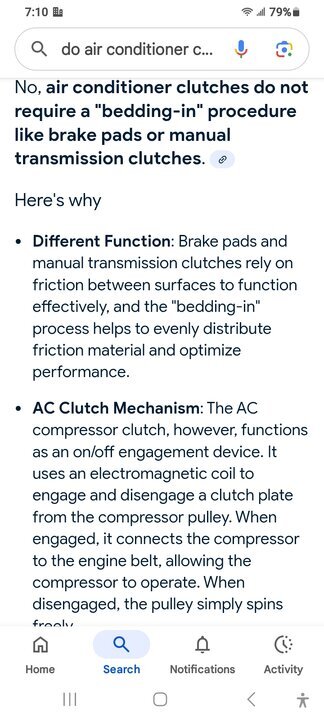

I have no idea what you're talking about when you say burnish im assuming you are referring to bedding/ transferring material from one surface to another ( like braking in brakes) if so i wouldn't worry too much about that . Pto clutches are metal to metal theres no resins to transfer . But i can tell you how to replace it. Assuming that you've removed any thing that is in the way .(aircleaner etc. ) if the clutch will still engage its easier to remove. So with the clutch in gaged and the Serpentine belt still on remove the center bolt. Youll see threds on the inside of the hole use appropriate size bolt and tighten to push the clutch off the shaft. Once it's free but still on the shaft go ahead and disengage the clutch and remove the Serpentine belt. Remove the clutch and electromagnet from the shaft. Be sure to not loose the woodruff key. Now to reinstall to set the spacing between the magnet and clutch can be done 2 ways one way is with 4 evenly spaced cardboard shims ( thats how i do it) but the other way is to evenly wrap electrical tape around the magnet. Enough that it fits snug in the clutch. Then with the woodruff key removed install the clutch and magnet as an assembly put the center bolt in to hold it all together on the shaft. Rotate the assembly to align the magnet with the 4 bolt holes be mindful of the position of the power wire. Install the 4 bolts and tighten. Remove the clutch. Remove the tape used for spacing. Install the woodruff key install the clutch and center bolt . Check to make sure that the clutch doesn't rub on the magnet install the Serpentine belt hookup power energize the clutch and torque center bolt to spec and you B done. Hope this helps. I use 4 pieces of thin cardboard because that way i can put it all together and reach behind and pull out the strips and not have to go thru the redundant steps in order to remove the tape used for spacingGetting ready to do my first clutch tomorrow. I'v researched everything I can find online. Engine off to burnish? Get it off with a bolt not a puller? Will I need to use a gauge or tape to set a clearance? Any helpful tips so I don't screw it up would be helpful. Got the clutch from Napa. Oh and someone said to turn on the pump clutch when burnishing the new clutch?

Last edited:

Why??? Ya tryin to wear out the switch??? I told ya and i showed ya there's no such thing a bedding an electric clutch of this type and whoever told you that doesn't know or understand what there talking about.I'v heard you shoud turn the cds key on 5 seconds off 5 seconds a bunch of times.

fredtestseven

Member

- Joined

- Aug 9, 2012

- Messages

- 22

Well Ogura, Pitts, etc say you don't know wtf you are talking about and they make the things.Why??? Ya tryin to wear out the switch??? I told ya and i showed ya there's no such thing a bedding an electric clutch of this type and whoever told you that doesn't know or understand what there talking about.

I didn't want to post and I PMd him the other day but I don't want others following your bad advice. Most manufacturers call for the key on 5 sec on then off cycle 25-40 times to burnish a new em clutch. Not doing so potentially reduces its torque handling capabilities significantly.

Electromagnetic Clutches and Brakes - Ogura Industrial Corp -

Electromagnetic Clutches and Brakes - Ogura Industrial Corp -

The Basics of Electromagnetic Clutches and Brakes

Electromagnetic clutches and brakes seem simple, but complex variations fit them to multiple applications.

be careful who you listen to folks...

in case Dwayne needs a google screenshot since I know he loves them

AI/google is not a substitute for critical thinking and proper research especially if you don't know what questions to ask

*the caveat to this is clutches that are specifically listed as pre-burnished

Last edited:

Jim Pemberton

MB Exclusive.

- Joined

- Oct 7, 2006

- Messages

- 12,687

- Name

- Jim Pemberton

We burnish clutches on Hydramaster CDS units per manufacturer's directives. We also do it on Pro 1200 SE units.

A customer of ours bought a clutch, installed it himself, and didn't burnish it. Within a month he had to get another, we installed and burnished, and a few years later all is still good.

A customer of ours bought a clutch, installed it himself, and didn't burnish it. Within a month he had to get another, we installed and burnished, and a few years later all is still good.

hogjowl

Idiot™

Does Hydramaster not have a service rep you can call to gain this information?

By the way, this is a serious question. The impression I’ve gained over the years is that HM owners have no direct support from HM itself.

By the way, this is a serious question. The impression I’ve gained over the years is that HM owners have no direct support from HM itself.

Last edited:

If you're talking about the pots on the throttle controller it really doesn't matter what you're doing with the vacuum. You are setting engine rpm and the controller will adjust the rpm up or down as necessary as load is applied or removed to maintain the rpm you set. In other words if you set the no load rpm of the engine @ 1300 the controller will add more "gas pedal " as load is applied. With a controller you're setting rpm. However ever if you had a system like old steamgenis used where you had a solenoid that pulled the gas pedal to a fixed position then you would set rpm under load. Think of it like climbing a hill as you go up you give it more gas to maintain speed. Thats what a throttle controller does. However if you had a solenoid type throttle system it would be like hold ing your foot in the same position while climbing and the vehicle would go slower and slowerThanks Jim. I screwed with the vac relief and throttle pods when this started. What's the best way to set the rpm's and vac relief? I was thinking primary pod, vac relief and then secondary pod?

Cleanworks

Moderator

I have good support from Hydramaster locally. I have a Hydramaster rep who does my maintenance and the headquarters is just over the border from me.Does Hydramaster not have a service rep you can call to gain this information?

By the way, this is a serious question. The impression I’ve gained over the years is that HM owners have no direct support from HM itself.

Bryce C

DFW

Does Hydramaster not have a service rep you can call to gain this information?

By the way, this is a serious question. The impression I’ve gained over the years is that HM owners have no direct support from HM itself.

Jim P introduced me to a friend of his who is a Hydramaster Tech at MF that has been my right hand man second to Dwain-o learning how to troubleshoot this machine. I text and call him and he gets right back to me, super helpful.

My latest problem was with the throttle again, I was in the field and I called him asking about the issue of slowly losing rpms (new phenomenon). Didn't have time to post it to the boards. He had me check a few things and we figured out quick that my brake pedal sensor was out just enough to trigger a safety mechanism in my throttle controller. I bungee strap my brake pedal upwards when I am on site and haven't had a problem since. I really need to go to the Chevy dealer and buy that new brake pedal sensor for $15.

Is it the switch or some sorta spring return on the pedal it's self? If you can hold the brake pedal up with a bungee strap and the switch works perhaps its something as simple as a spring. I don't know about your van but in the research on mine if you can believe this, on a 2020 chevy express the brake light switch must be programed when installed! And that my friend is the stupidest thing i have ever heard but its true. Till the 2020 the newest chevy van i have had experience working on is 2001 and that was not necessary on it but you might checkJim P introduced me to a friend of his who is a Hydramaster Tech at MF that has been my right hand man second to Dwain-o learning how to troubleshoot this machine. I text and call him and he gets right back to me, super helpful.

My latest problem was with the throttle again, I was in the field and I called him asking about the issue of slowly losing rpms (new phenomenon). Didn't have time to post it to the boards. He had me check a few things and we figured out quick that my brake pedal sensor was out just enough to trigger a safety mechanism in my throttle controller. I bungee strap my brake pedal upwards when I am on site and haven't had a problem since. I really need to go to the Chevy dealer and buy that new brake pedal sensor for

Last edited:

hogjowl

Idiot™

I had a brake sensor problem on my Cleanco. I bought two aftermarket sensors and they both wouldn’t work. Went the Chevy dealer and bought one of theirs and it worked.

hogjowl

Idiot™

It’s a switch on the pedalIs it the switch or some sorta spring return on the pedal it's self?

It’s a switch on the pedal

What year is your van? Did the switch have to be programed after installation?I had a brake sensor problem on my Cleanco. I bought two aftermarket sensors and they both wouldn’t work. Went the Chevy dealer and bought one of theirs and it worked.

hogjowl

Idiot™

2015. No it just screws onto the pedal and the brake boosterWhat year is your van? Did the switch have to be programed after installation?

He's probably the same then his is a 13. Mines a 2020 and requires reprogramming inorder to work.2015. No it just screws of the pedal and the brake booster

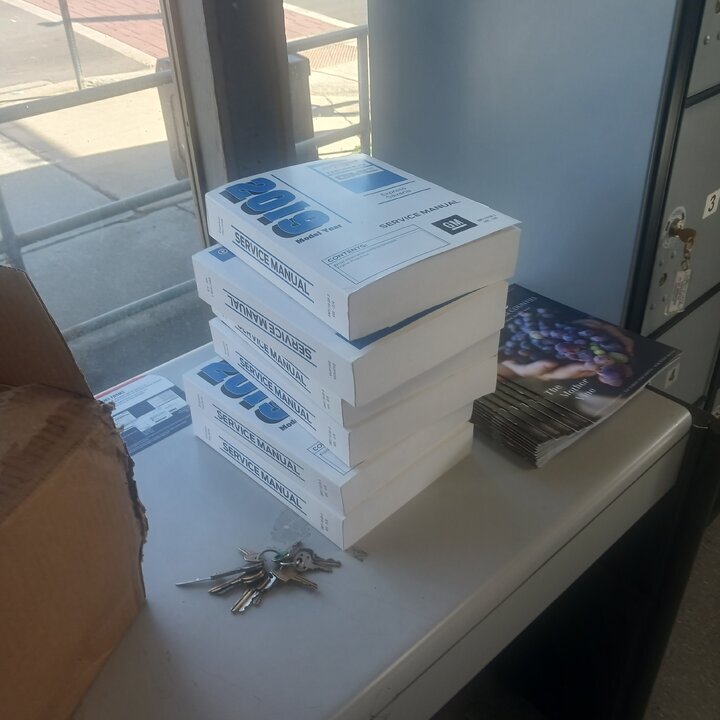

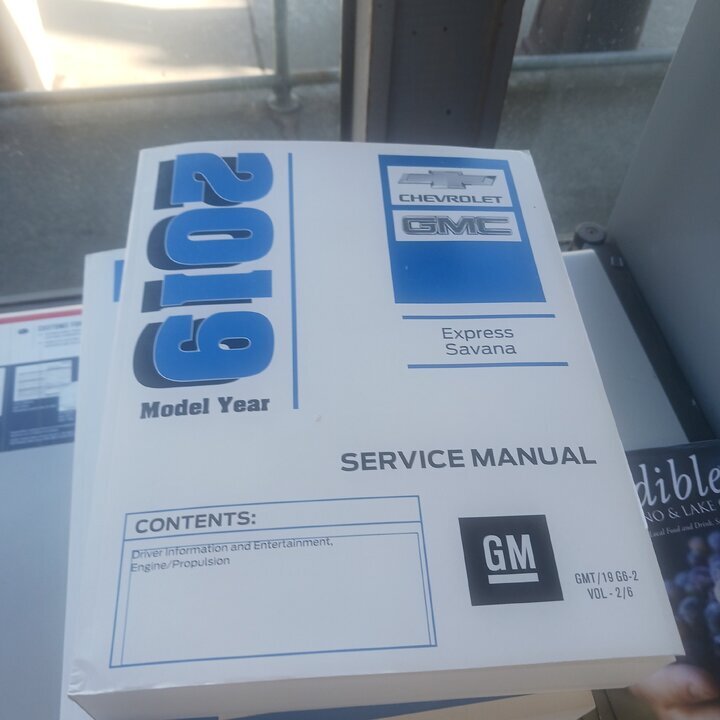

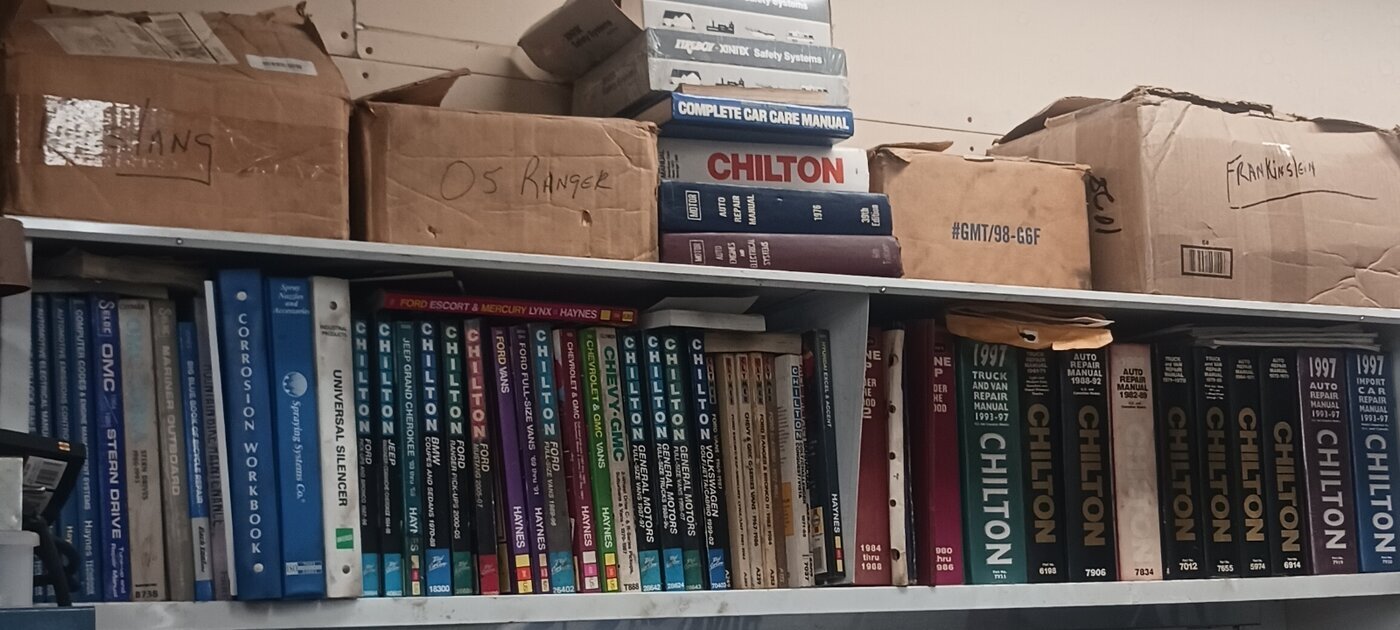

When i buy a vehicle the first purchase i make afterwards (if i can't trick the saleman to add it as condition of sale) is complete helms factory service manuals. Everything that the dealership has on computer i have in book form there year and model specific but are generally good for several years my 2000 i still use the manuals for my 98 and i couldn't get one fot a 2020 so i settled for a 2019. But interestingly the 1998 is 3 volume so is my 07 mustang and 05 ranger but the 2019 chevy is 6 volume s theres that much more shit to do and go wrong in guessing till resently the van's been under warranty and ive only used the manuals for frankinstien's install even then just for wiring info and component locations. I relyed more on the cleanco dealers install 200 page pdf for most because i used a cleanco drive and coolant taps and the same throttle controller